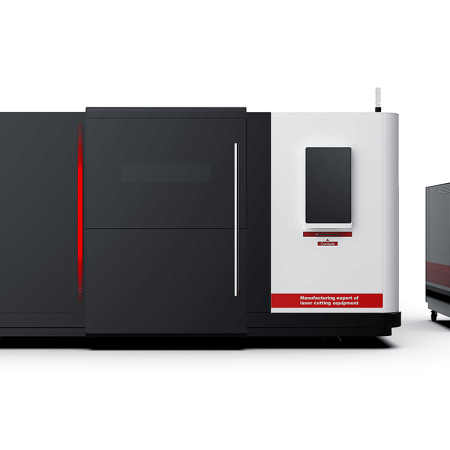

Definition Of 3D Fiber Laser Machine

A 3D fiber laser cutting machine from 3d fiber laser cutting machine supplier is a type of industrial cutting equipment that uses a high-power fiber laser to cut through various materials with great precision and accuracy. It is capable of cutting through metals, plastics, ceramics, and other materials, with thicknesses ranging from thin sheets to thicker plates.

Unlike traditional cutting methods that use mechanical blades, the fiber laser cutting machine uses a concentrated beam of light that is directed through a series of mirrors and lenses to the workpiece. This allows for more precise and intricate cuts, as well as the ability to cut complex 3D shapes and contours.

The fiber laser cutting machine is also known for its speed and efficiency, as it can cut through materials quickly and with minimal waste. It is widely used in industries such as aerospace, automotive, electronics, and manufacturing, where precision cutting is essential for creating high-quality products.

Benefits About 3d Fiber Laser Cutting Machines

There are several benefits to using a 3D fiber laser cutting machine for industrial cutting applications:

High precision: The fiber laser technology offers extremely accurate and precise cuts, even on complex 3D shapes and contours. This allows for a higher degree of accuracy and repeatability, which is important in manufacturing and fabrication.

Speed and efficiency: Fiber laser cutting machines are capable of cutting through materials quickly and with minimal waste, which increases productivity and reduces material costs.

Versatility: The 3D fiber laser cutting machines can cut through a wide range of materials, including metals, plastics, ceramics, and more, with thicknesses ranging from thin sheets to thicker plates.

Low maintenance: The fiber laser technology is highly durable and requires minimal maintenance, which reduces downtime and increases efficiency.

Environmentally friendly: Unlike traditional cutting methods that generate a lot of waste and produce harmful emissions, fiber laser cutting machines produce less waste and have a smaller environmental impact.

Cost-effective: While the initial investment in a fiber laser cutting machine may be higher than other cutting technologies, the long-term cost savings from increased productivity and reduced material waste make it a cost-effective option for many industries.