Laser cutting is a modern-day innovation in which a high-powered laser is directed at the preferred surface area to cut various forms and types. The product usually burns or melts, leaving a top quality surface finish. Because there is no straight contact in between the laser and also the surface in operation, the level of accuracy and accuracy in the laser cutting process is far more as contrasted to standard approaches.

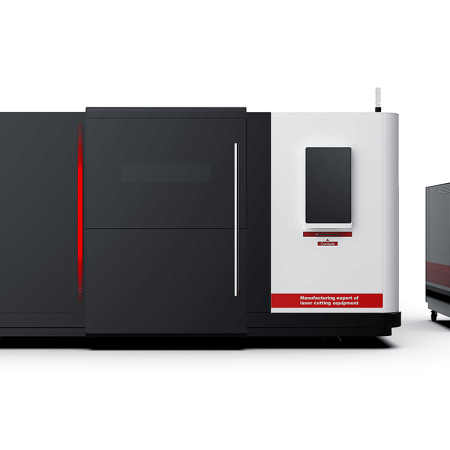

As a result of its precision as well as effectiveness, laser cutting is made use of to reduce a wide range of materials. Metal is one such typical application. Because ancient times, metals have been extensively made use of for a number of functions. From tools and also accessories to building and also packing product, the importance of steels in our day-to-day lives can not be denied. Metal Sheet Laser Cutting Machine manufacturer Today, with the development of fiber optics as well as information technology, metals have actually gotten a very particular role. Because traditional processing techniques can not be sufficient all these modern needs, laser cutting is being thoroughly made use of in steel handling.

Apart from the normal CO2 laser used in many processes, metal cutting employs the use of three other procedures, namely Oxygen reducing, Nitrogen cutting as well as Sublimation cutting. The oxygen process develops much more warmth on account of the reaction in between the metal and the gas. The added heat aids in the reducing process. On the other hand, when an inert gas like nitrogen is utilized for cutting the metal, extra power is needed.

Since steels are good conductors and also reflectors of heat, the intensity of the laser requires to be modified, relying on the nature of the steel. The laser beam is led around the metal surface area to get the preferred form.

Laser metal cutting deals a number of benefits over the various other procedures such as plasma cutting, water-jet cutting as well as flame cutting. The laser procedure is not just faster than the other methods, however likewise supplies unequaled degrees of accuracy and high quality. The opportunities of damaging the surface being cut are likewise minimized.