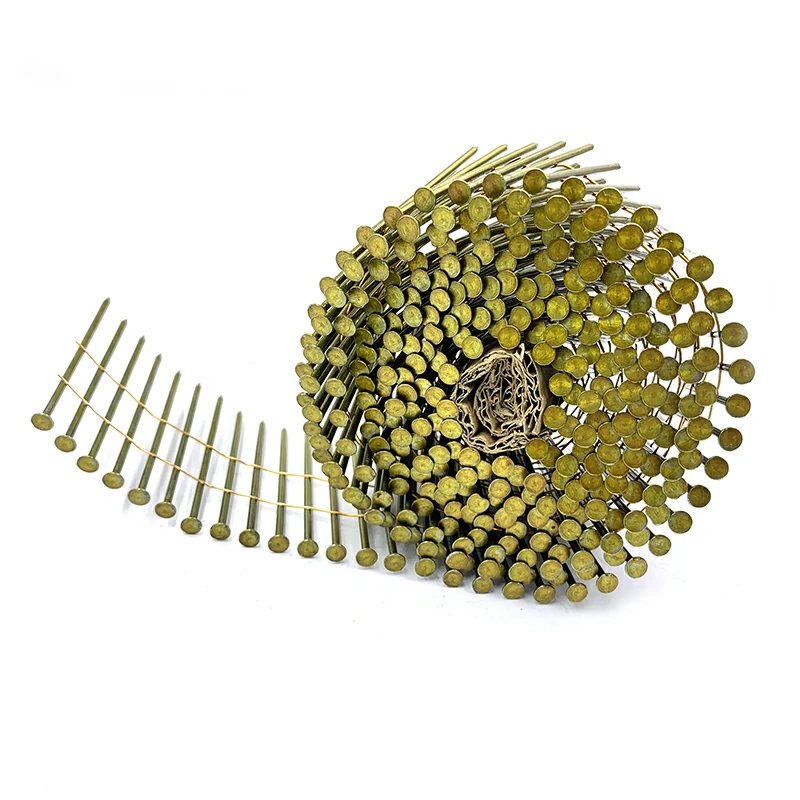

The material selection for 3-inch coil nails can have a significant impact on their overall cost-effectiveness.

Here’s how different materials may influence cost-effectiveness:

- Stainless Steel: While stainless steel nails typically have a higher upfront cost compared to other materials, they offer excellent corrosion resistance, durability, and longevity. Stainless steel nails are ideal for outdoor applications and environments prone to moisture, humidity, or corrosive elements. Despite the higher initial cost, stainless steel nails can be more cost-effective in the long run due to their extended lifespan and minimal maintenance requirements, reducing the need for frequent replacements.

- Galvanized Steel: Galvanized steel nails are coated with a layer of zinc to enhance corrosion resistance. They are generally more affordable than stainless steel nails and offer good durability and protection against rust in moderately corrosive environments. Galvanized steel nails may be a cost-effective option for indoor applications or environments with less exposure to moisture and corrosive elements.

- Carbon Steel: Carbon steel nails are the most economical option upfront but are more susceptible to corrosion compared to stainless steel or galvanized nails. They may be suitable for temporary or indoor applications where corrosion resistance is not a primary concern. However, in humid or corrosive environments, carbon steel nails may require frequent maintenance and replacement, leading to higher long-term costs.

- Aluminum: Aluminum nails offer lightweight and corrosion-resistant properties, making them suitable for certain applications, such as trim work or light-duty fastening tasks. While aluminum nails may have a higher initial cost compared to carbon steel, 3 inch coil nails they are generally more affordable than stainless steel nails. However, aluminum nails may not be as strong as steel nails and may not be suitable for heavy-duty or load-bearing applications.

- Composite Materials: Some manufacturers offer composite or polymer-coated nails designed to provide corrosion resistance and durability while reducing the risk of surface damage to materials. While these nails may have a higher initial cost, they offer benefits such as reduced risk of staining or discoloration of materials and improved fastening performance. Depending on the specific application and requirements, composite nails may offer a cost-effective solution compared to traditional metal nails.

Overall, the material selection for 3-inch coil nails should be based on factors such as the application requirements, environmental conditions, durability expectations, and budget constraints. While stainless steel nails may offer the highest level of corrosion resistance and longevity, other materials such as galvanized steel or composite options may provide a more cost-effective solution for certain applications. It’s essential to evaluate the total cost of ownership, including maintenance and replacement expenses, to determine the most cost-effective option for your specific needs.